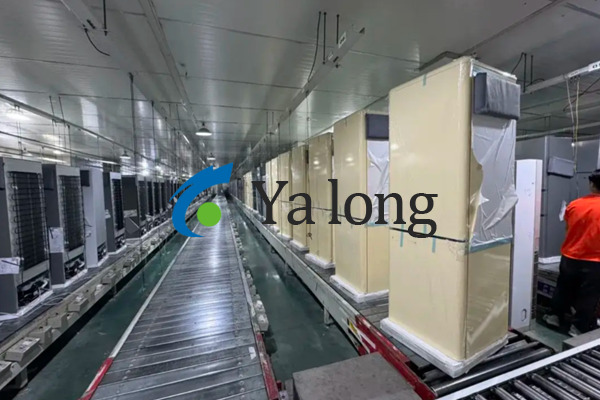

Refrigerator assembly line: differentiated intelligent assembly system for large/small refrigerators

Aiming at the production differences between large refrigerators (double door/multiple doors ≥400L) and small refrigerators (single door/mini <150L), the refrigerator assembly line customizes a split-line solution, integrating heavy-duty transportation, flexible adaptation and intelligent control modules, covering the entire process of foaming, assembly, filling, and testing, taking into account the needs of precision manufacturing and efficient mass production.

1. Differences in core transportation and process

(1) Large refrigerator production line Transportation: heavy-duty double-speed chain (tooling plate ≥1200×800mm, load bearing 500kg)+ heavy-duty carrier (lifting force ≥1 ton, positioning ±0.5mm) Process: two-component high-pressure foaming (flow error ±1.5%), six-axis robot door body assembly (hole position ±0.1mm), high-precision refrigerant filling (±1g)

(2)Small refrigerator production line Conveying: Light roller line (speed 15-25m/min)+ adjustable fixture (30-120L quick fit) Process: low-pressure foaming (saving 30% energy consumption), pneumatic booster arm door body assembly, regular quantitative filling (±5g)

2. Intelligent control and core advantages

(1) Large refrigerator: precision + stability Digital twin pre-debugging, foaming constant temperature ±0.5℃, laser ranging to solve poor sealing strip fit (pressure ±2N) Single unit consumes 18-22kWh, and fails response ≤15 minutes

(2)Small refrigerator: flexible + efficient Scan code and quickly change (<5 minutes), acoustic detection of abnormal sound of compressor, 3D vision avoidance of pipeline interference A single unit consumes 3-5kWh, and a minimum batch of 10 units can be mass produced